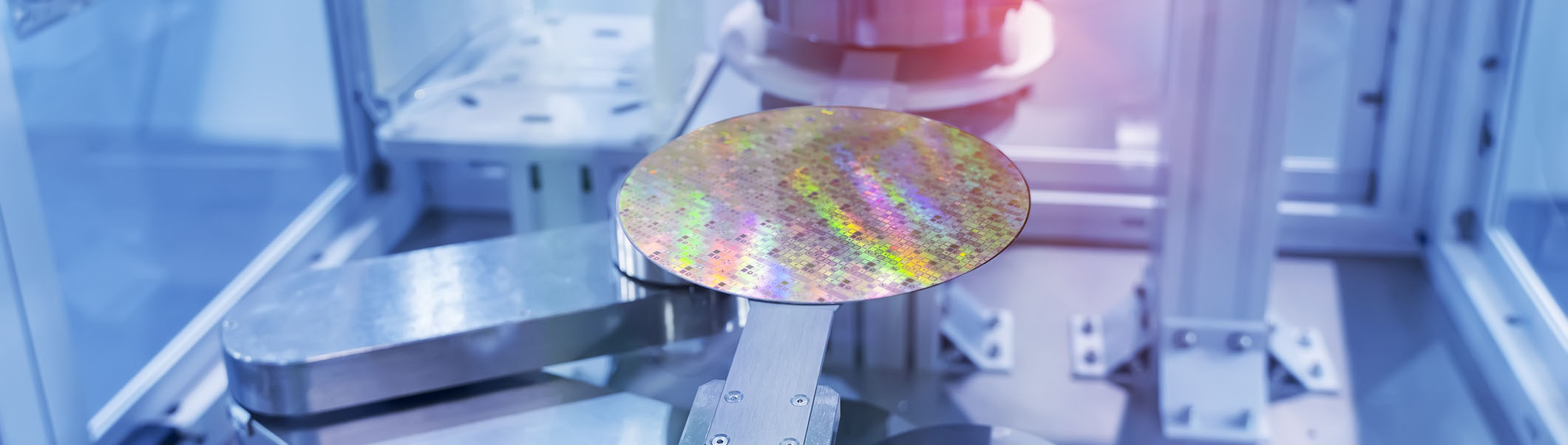

Lynceus is proud to partner with NXP semiconductors for the qualification of AI tools for automotive chip production. Together with NXP, we presented a case study at the most recent Fab Owners Association (FOA). Read more here: https://www.semiconductor-digest.com/lynceus-and-nxp-semiconductors-partner-to-qualify-ai-for-automotive-chip-production/