Lynceus Augmented Metrology

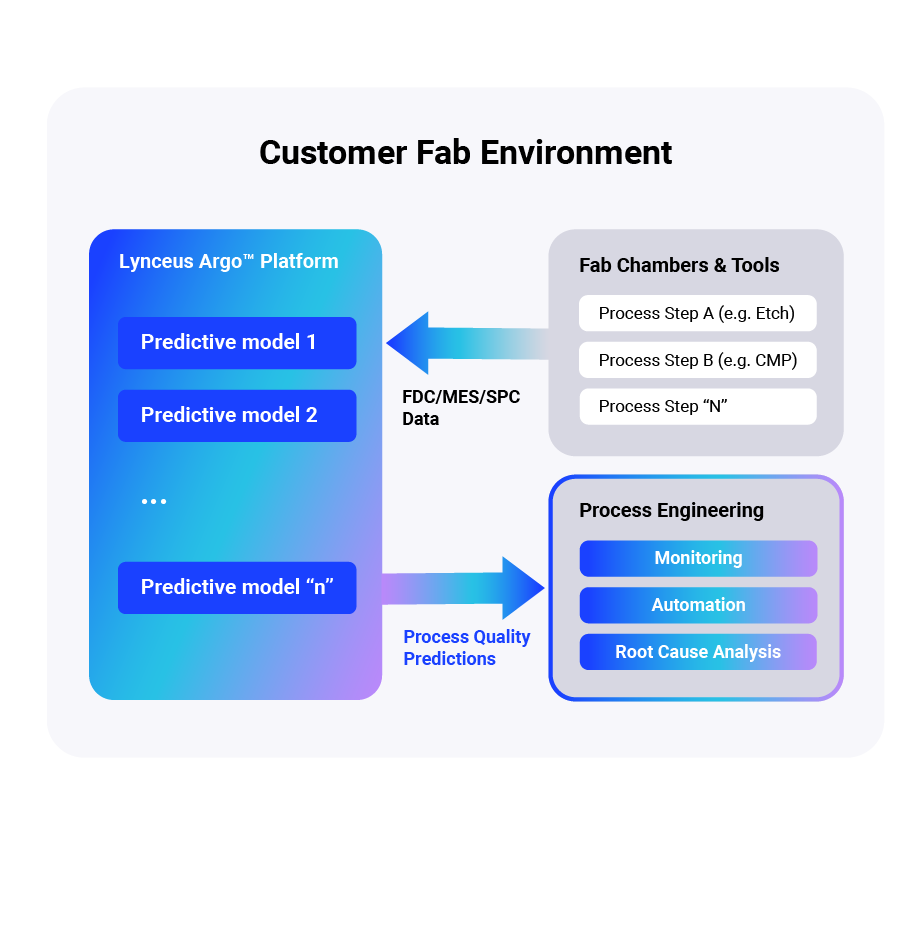

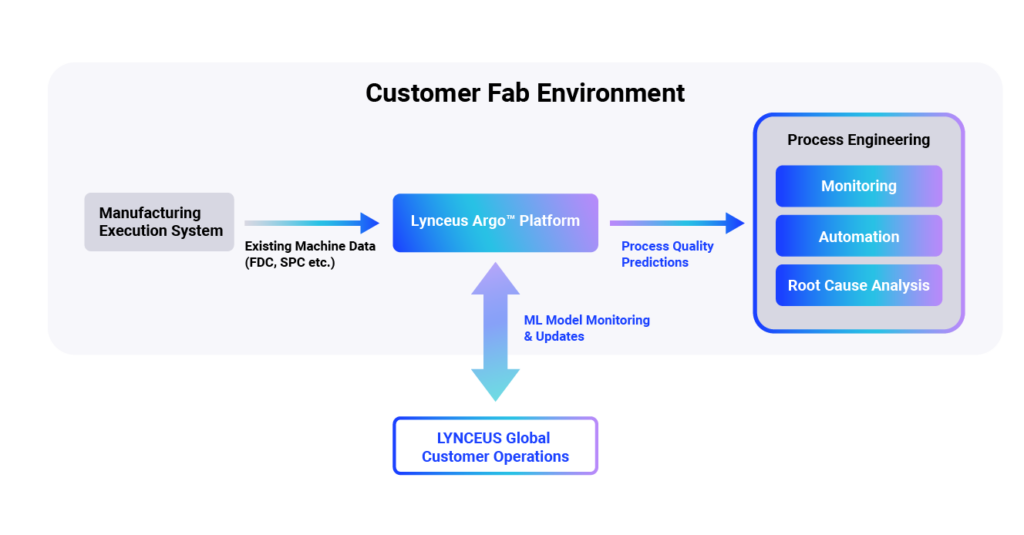

Lynceus Augmented Metrology uses existing process data (FDC, tool utilization) to inform process engineers in real-time on whether a wafer should be sent to metrology or not

Engineers don’t need to wait for the results of physical quality tests to know if they are producing good or bad units

In the event of an excursion, engineers can react immediately with context-driven drill-downs that enable them to identify the root cause and take necessary actions.