Lynceus is one of the most interesting start-ups out in the semiconductor industry. They aren’t focused on making or designing chips, instead they are focused on software that runs in fabs. Before we dive into their solution, we want to provide some background. Most fabs use various inhouse and external software’s across their fabs. A player like PDF Solutions might provide the database and process solution for tying everything together, various tool companies will provide software for their own tools, and software from the leading inspection and metrology providers such as KLA, Onto, and Nova Measuring Instruments will help identify defects.

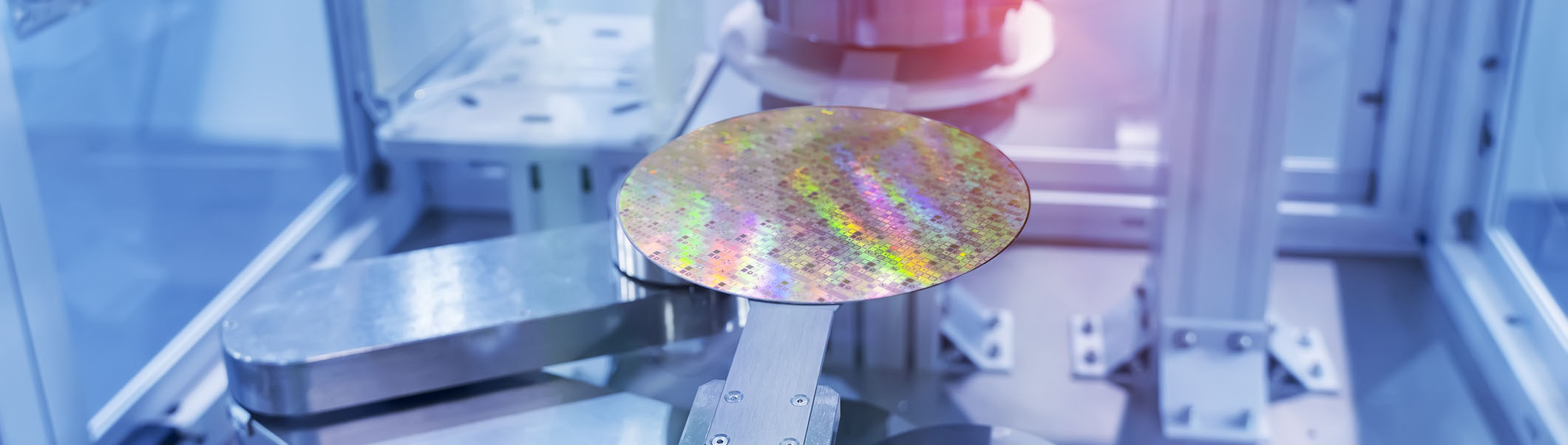

This is where Lynceus comes in. They take data generated from wafer fabrication tools, existing data a fab has on their high-volume manufacturing lines, and build in real-time process control. All data would be fed into various AI models, and they can help identify issues for process and yield engineers. More rapid root cause analysis would help direct the fab’s engineers on critical problems and not waste time on non-issues, increasing engineer efficiency. Another big advantage is that they could start to reduce the amount of inspection and metrology done to optimize the amount of capex and floorspace dedicated to those types of tools that do not advance the manufacturing of a wafer.

To read the full article, click here: https://www.semianalysis.com/p/lynceus-inline-real-time-ai-based